HISTORY

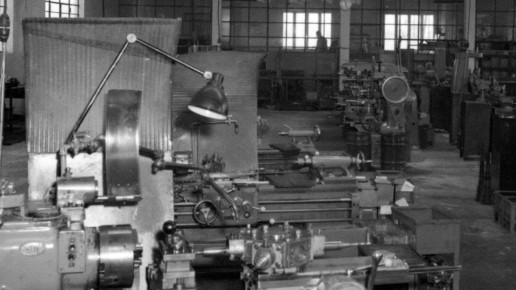

Mr. Pierino Cattini matured a significant technical background during the second world war, where his task consisted in producing gears and other sophisticated components for military vehicles and ships.

After the war, Mr. Cattini started his own business under the strategy to endlessly expand the production program of his Company to become and remain one of the preeminent suppliers of transmission gears in the continent.

He also saw it necessary for the long-term future of the Company to diversify his business. The acquisition of new customers in different market segments and entrance in the OEM business quickly increased revenues, and acquired market recognition in a fiercely competitive arena at that time.

Coherent with this strategy, beyond the cylindrical gears produced from the very beginning, Mr. Cattini started to serve the agricultural tractor OEMs in the early ‘60s and to produce spiral bevel gears in the mid ‘60s.

We are especially proud that, after almost 60 years, these first OEM Customers are still part of our network today.

From then on, quality requirements and expectations in the industry have steadily increased and so did our capabilities in terms both of technological innovation and of management of complex tasks, always with the clear goal in mind to achieve highest customer satisfaction and continuous development of our business.

In 1973, planetary ring gears were added to our product portfolio and in the second half of the ‘80s, technological studies were in place for the introduction of the manual gear shifting systems which were launched in 1991.

The last complement to our range are power-shift gear shifting systems produced since 2010, which bring with them electron beam welding technology that, again, Cattini mastered to cater to customers’ need for reliable, heavy duty, welding processes.

A further innovation was the introduction of the shot peening process from 2014, which we developed with the support of one of our technological partners, as well as the closed loop methodology, introduced in 2019 for the involute grinding of cylindrical gears. After many years of experience in spiral beveled gears, this sophisticated methodology is available for cylindrical gears as well, providing greater reliability and productivity of the grinding process, allowing production and measuring machines to communicate directly without manual input.

Cattini’s strategy for the future is powered by an ambition to endlessly grow and maintain a strong presence in the power transmission segment, to stand as a trusted supplier and partner for its customer whilst preserving the Company’s strong family values for all Associates and Stakeholders.

Transforming a tough task into a winning solution: that is the Cattini way of life!

TIMELINE

1949

Hay elevators

1950

Cylind. gears

1965

Bevel gears

1973

Planetary gears

In 1973, planetary ring gears were added to our product portfolio and, in the second half of the ‘80s, technological studies were in place for the introduction of the manual gear shifting systems which were launched in 1991.

The last complement to our range are the power-shift gear shifting systems which were produced from 2010, bringing with them the electron beam welding technology which, again, Cattini mastered to cater Customer’s need for reliable, heavy duty welding process.

A further innovation was the introduction of the shot peening process from 2014 which we developed with the support of one of our technological Partners and, finally, the closed loop methodology which was introduced in 2019 for the involute grinding of cylindrical gears. After many years of experience in spiral bevel gears, this sophisticated methodology is available for cylindrical gears as well, providing increased reliability and productivity of the grinding process, making possibile for production and measuring machines to communicate directly with no manual input.

Cattini’s strategy for the future is fuelled by ambition, ambition to endlessly grow to remain a strong presence in the power transmission segment, to remain a Partner supplier for its Customers, to remain a Company with strong family values for all Associates and Stakeholders.

Transforming a tough task into a winning solution: this is the Cattini way of life!

TIMELINE

1991

Sinchronizers

1998

Press quenching heat treatment

1998

Bevel gear grinding

Foto isola Liebherr o Viper

Foto isola G 60

Foto Praewema sincro

TIMELINE

2001

High speed cylindrical gear grinding

2014

EBW & Shot peening

2019

Power skiving & int. gear grinding